Introduction – The Need for Effective Robotic Welding Fume Extraction

Common Fume Extraction Challenges in Robotic Welding Cells

Robotic welding environments present unique ventilation challenges. Unlike manual stations, robotic welding cells are enclosed, high-precision workspaces that often operate continuously. These conditions result in a dense concentration of harmful fumes, making localized extraction and airflow design critical.

Facilities working with automated welding cell hoods or custom robotic welding ventilation hoods must address:

Confined space accumulation of fumes and metal particles

The need for continuous extraction during 24/7 operations

Protecting robotic arms, sensors, and optical systems from contamination

Ensuring compliance with OSHA and other international safety standards

To effectively mitigate these risks, industrial-grade robotic welding fume extraction systems are deployed, incorporating high-efficiency filtration, programmable suction, and modular design for scalability.

Recommended Robotic Welding Fume Extraction Solutions

Robotic welding operations present a unique set of challenges when it comes to fume extraction. Unlike manual welding, these systems often operate continuously in confined, automated environments—generating a concentrated volume of fine metal particles, fumes, and gases. Selecting the right robotic welding fume extraction system is essential not only for air quality but also for equipment longevity and compliance with occupational health standards.

Below are the most suitable solutions for robotic welding fume control based on particle concentration, workspace layout, and operational needs:

Cyclone dust collectors are ideal as first-stage filtration systems. In robotic welding setups where large debris or coarse particles are generated—such as in plasma cutting cells or multi-process stations—a cyclone unit helps extend the life of the downstream filters by removing heavy contaminants before they reach the main system.

Suitable for: High-dust environments, heavy particulates, pre-filtration before HEPA systems

Not a standalone solution for robotic welding fumes

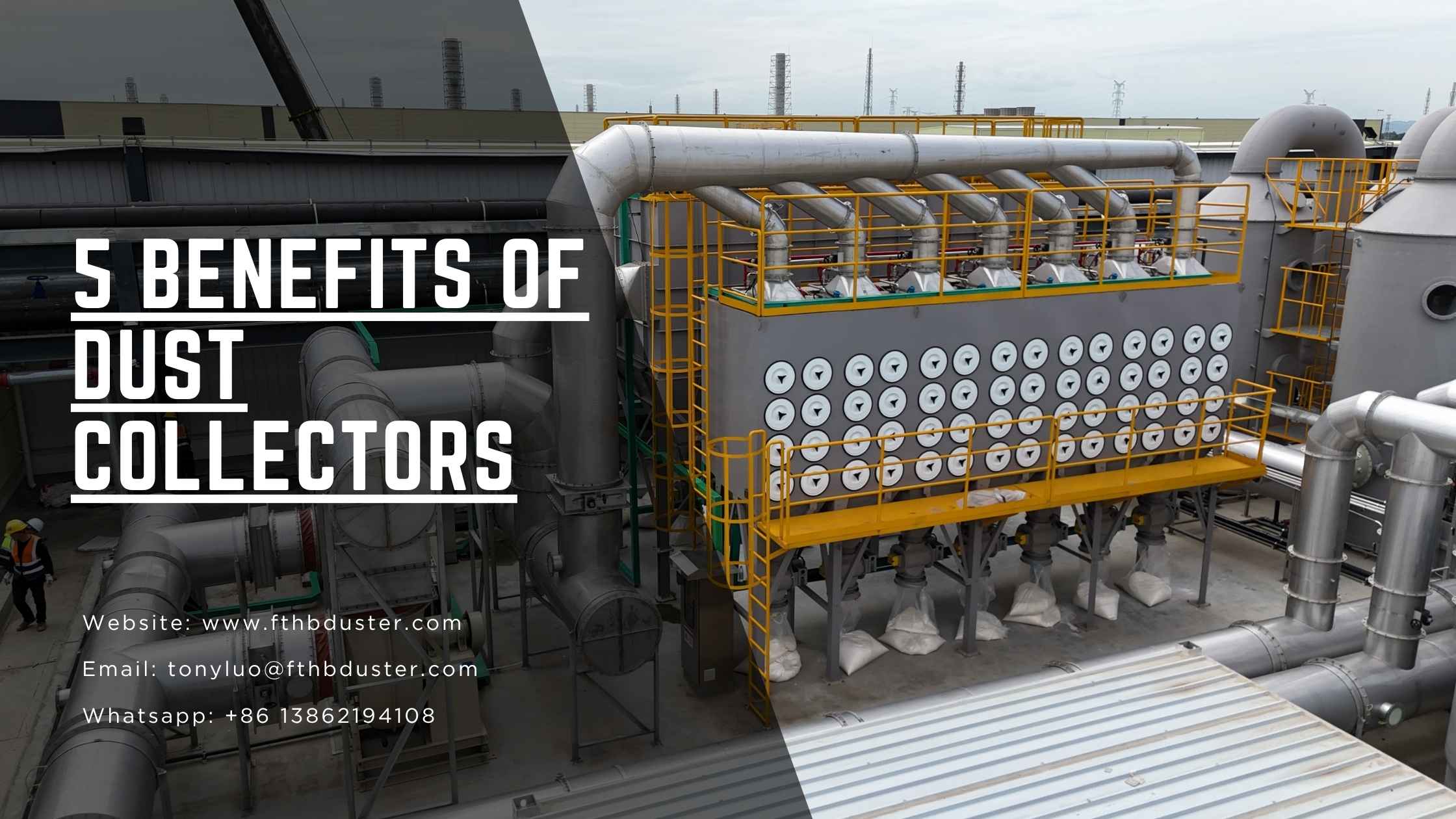

Cartridge-based dust collectors are the most widely used filtration systems for robotic welding applications. Their compact size and high-efficiency filtration make them ideal for automated welding cell hoods, especially when paired with source capture hoods or enclosure systems.

They provide powerful suction and filter fine particles effectively, ensuring a clean air environment even in high-throughput production.

Suitable for: Robotic welding cells with moderate to high fume output

Wet collectors are especially effective in applications where combustible or explosive metal dusts are a concern. For robotic welding of aluminum or magnesium alloys, where dry sparks pose safety hazards, a water-based filtration system is a reliable choice. These systems help reduce explosion risks and comply with NFPA and OSHA regulations.

Suitable for: Stainless steel welding, aluminum, explosive dust environments

Designed for demanding, non-stop production lines, sintered plate collectors are maintenance-free and highly durable. Their smooth surface prevents dust adhesion, making them ideal for robotic welding operations where minimal downtime and automated reliability are required.

These systems are particularly useful in automotive welding cells or muffler robot lines, where precision and cleanliness are critical.

Suitable for: 24/7 robotic welding lines, minimal maintenance environments

For flexible and temporary robotic welding setups, mobile fume extractors with articulating capture arms offer a quick and effective solution. These are perfect for spot welding robots, pilot runs, or facilities with frequent layout changes.

Easy to move and operate, they also serve as a backup during maintenance of centralized systems.

Suitable for: Robotic welding testing stations, prototype areas, small-scale automation

Summary Table

| System Type | Application Fit | Key Advantage | Notes |

| Cyclone Pre-Filter | Coarse particle removal | Extends main filter life | Must be paired |

| Cartridge Collector | Standard robotic welding cells | High efficiency, compact | Primary system |

| Wet Collector | Explosive metal fume | Fire-safe design | Regulatory compliance |

| Sintered Plate | 24/7 automated lines | Maintenance-free | High-end option |

| Portable Extractor | Flexible setups | Mobile and easy to use | Temporary/backup use |