What Is a Dust Collector and How Does It Work?

The 5 Overlooked Benefits of Dust Collectors

Extending the Life of Your Facility

Reducing Energy Consumption

Strengthening Your Brand Reputation

Enabling More Accurate Testing and R&D

Supporting Sustainability and ESG Goals

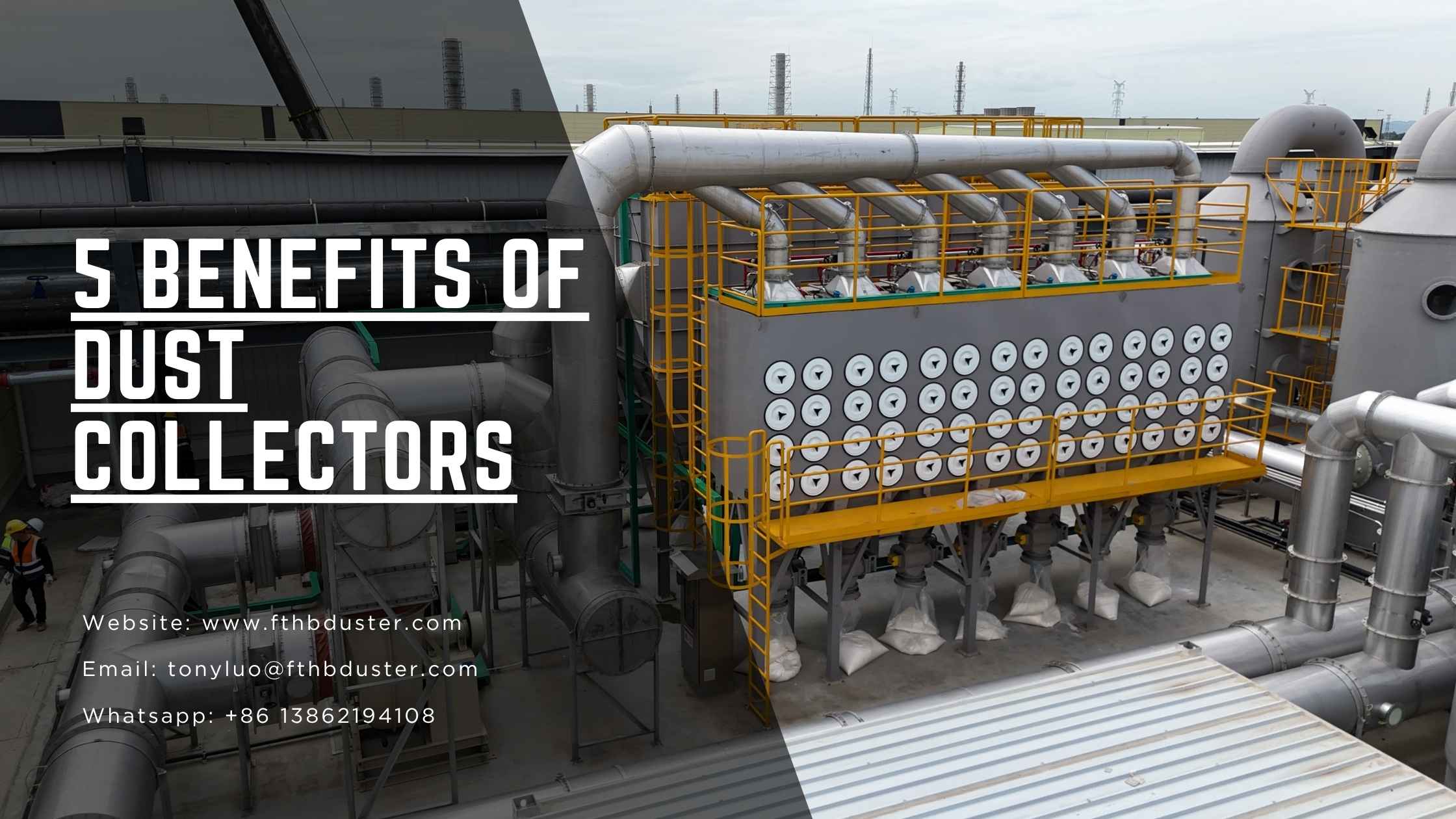

Why Global Manufacturers Trust FengTu®

Global Reach: From Asia to North America, we’ve deployed systems in over 20 countries

Total Customization: Each system is built-to-spec, based on your dust type, facility layout, airflow needs, and compliance requirements

Technical Expertise: Our engineers understand the behavior of different industrial dusts and design solutions around your unique challenges

Service and Support: From CFD simulation to onsite commissioning and training, we support you at every step

Ready to upgrade your dust control system? Contact FengTu® today for a free consultation and engineered quote.

FAQs

Why should I invest in a dust collector for my business?

Investing in a dust collector not only improves your workplace air quality but also protects your employees' health, reduces equipment maintenance costs, and ensures your operations comply with strict environmental regulations. With FengTu®’s high-efficiency dust collection systems, you’re investing in both the safety of your workforce and the longevity of your equipment, leading to increased productivity and profitability in the long run.

How does FengTu®’s dust collection system improve safety and prevent explosions?

Can a dust collector really improve product quality and reduce costs?

How does a dust collector help me stay compliant with environmental regulations?

What makes FengTu® dust collectors a cost-effective solution?