Overview

In our previous article, [What is a Baghouse Dust Collector], we covered the basics of what a baghouse system is and briefly touched on how it works. In this follow-up, Evan from FengTu® takes a deeper dive into the working principle of baghouse dust collectors, breaking it down with clear diagrams and practical explanations.

Tip: The working principle of a cartridge dust collector is quite similar to that of a baghouse. So even if you're exploring cartridge systems, this article can serve as a useful reference.

If you have any technical questions or need help choosing the right system, feel free to reach out to a FengTu® engineer — we’re happy to assist.

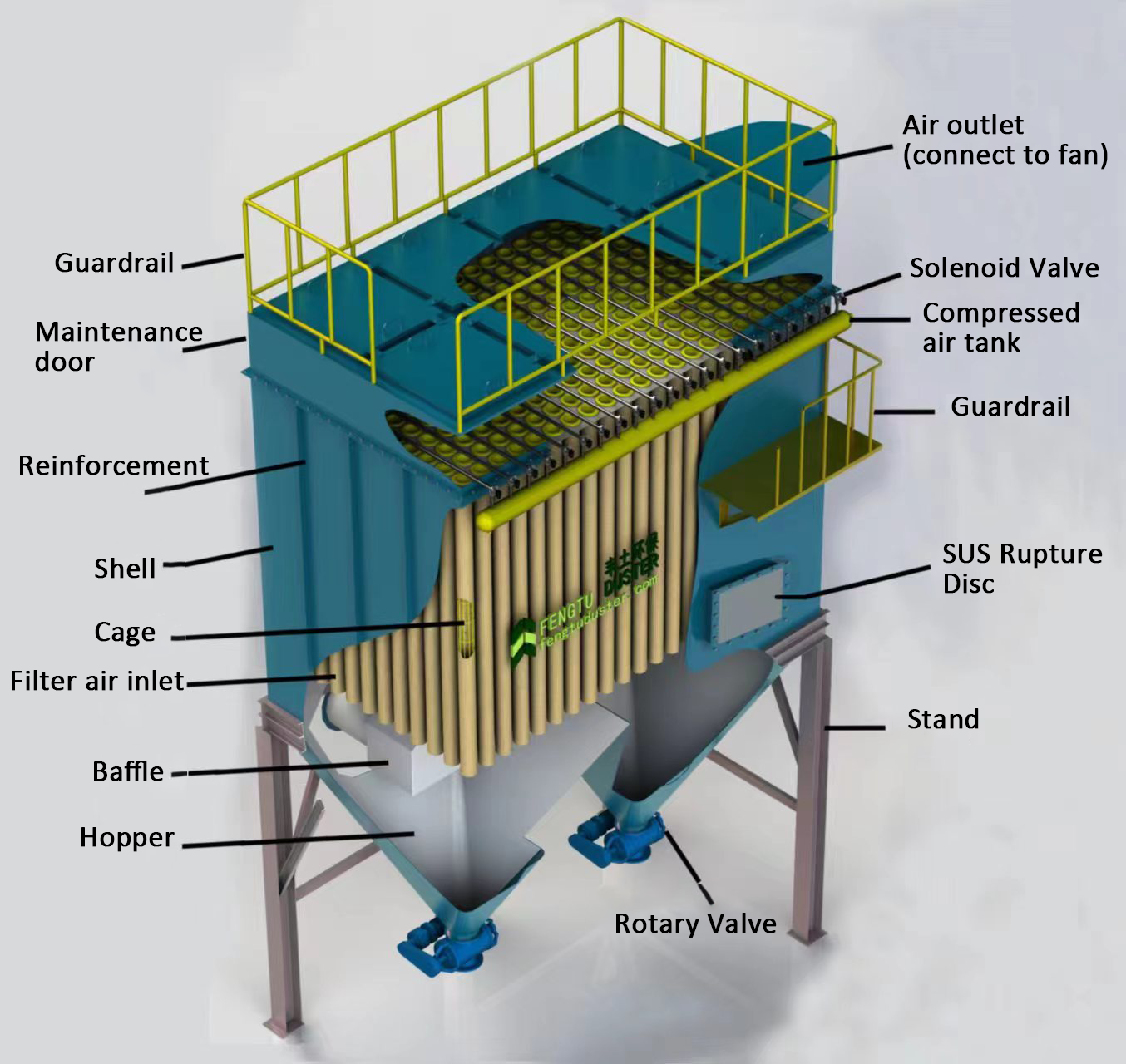

Understanding the Structure of a Baghouse Dust Collector

Please refer to the diagram below. A complete baghouse dust collector system typically consists of the following components:

Guardrail – for safe access during maintenance

Maintenance Door – provides entry for inspection and bag replacement

Reinforcement Frame – structural support for the main housing

Shell / Housing – the main body enclosing the filtration unit

Filter Cage – supports the filter bags and prevents collapse

Filter Bags – fabric filters that trap dust particles

Baffle Plate – helps distribute airflow and reduce turbulence

Dust Hopper – collects falling dust particles at the bottom

Rotary Airlock Valve – controls dust discharge from hopper

Support Stand / Structure – foundation support for the entire unit

SUS Rupture Disc (Stainless Steel) – explosion venting for pressure relief

Compressed Air Tank – stores high-pressure air for cleaning pulses

Solenoid Valves – control the release of compressed air for cleaning

Air Inlet & Outlet Ducts – channels for dirty air entry and clean air exhaust

How Does a Baghouse Dust Collector Work?

Evan takes the example of a pulse jet baghouse dust collector using standard cylindrical filter bags to illustrate the process. The operation is straightforward and easy to understand:

A high negative pressure fan draws in dust-laden air from the workshop into the dust collector. As the air flows through, fine dust particles are captured on the surface of the filter bags, while the cleaned air exits through the outlet. Once the system reaches a preset time or pressure differential threshold, the cleaning mechanism activates, pulsing compressed air to dislodge the accumulated dust into the hopper below.

In the following sections, we’ll break down each stage of the filtration cycle to help you better understand how the system works in detail.