Hi, this is Evan, an engineering designer with over 15 years of experience in the industrial dust collection industry. Today, I would like to introduce and recommend the most suitable industrial dust collectors for blasting operations, helping you choose the right solution for your factory. Since every working condition is different, my recommendations here will remain somewhat general. If you would like to discuss a tailored design, or entrust us with manufacturing your dust collector, please submit the form or contact me via email—I will reply within 24 hours. We also operate two modern industrial production bases, ensuring we can fully meet your requirements.

Our Quick Recommendation: For most blasting dust collector applications, your first choice should be a baghouse dust collector or a cartridge dust collector. These two types of dust collection system for sandblasting are highly efficient and versatile.

Why is Dust Control Crucial for Your Blasting Operations?

Blasting, including sandblasting and bead blasting, creates a massive amount of fine dust. If left uncontrolled, this dust can lead to serious problems:

Health and Safety Risks: Fine abrasive particles can be inhaled, causing respiratory illnesses for your workers.

Reduced Visibility: The high concentration of dust makes it difficult for operators to see, slowing down work and increasing the risk of accidents.

Equipment Damage: Dust can clog machinery and electrical components, leading to frequent maintenance and costly downtime.

Poor Product Quality: Dust settling on newly blasted surfaces can compromise the finish and quality of your final product.

Common Dust Issues in Blasting Operations

Whether you are using a blast cabinet or a larger blast room, the core challenge remains the same: capturing fine, abrasive dust. This is why a simple cyclone dust collector is often insufficient on its own. While they can capture larger particles, the fine dust easily escapes, requiring an additional filtration stage.

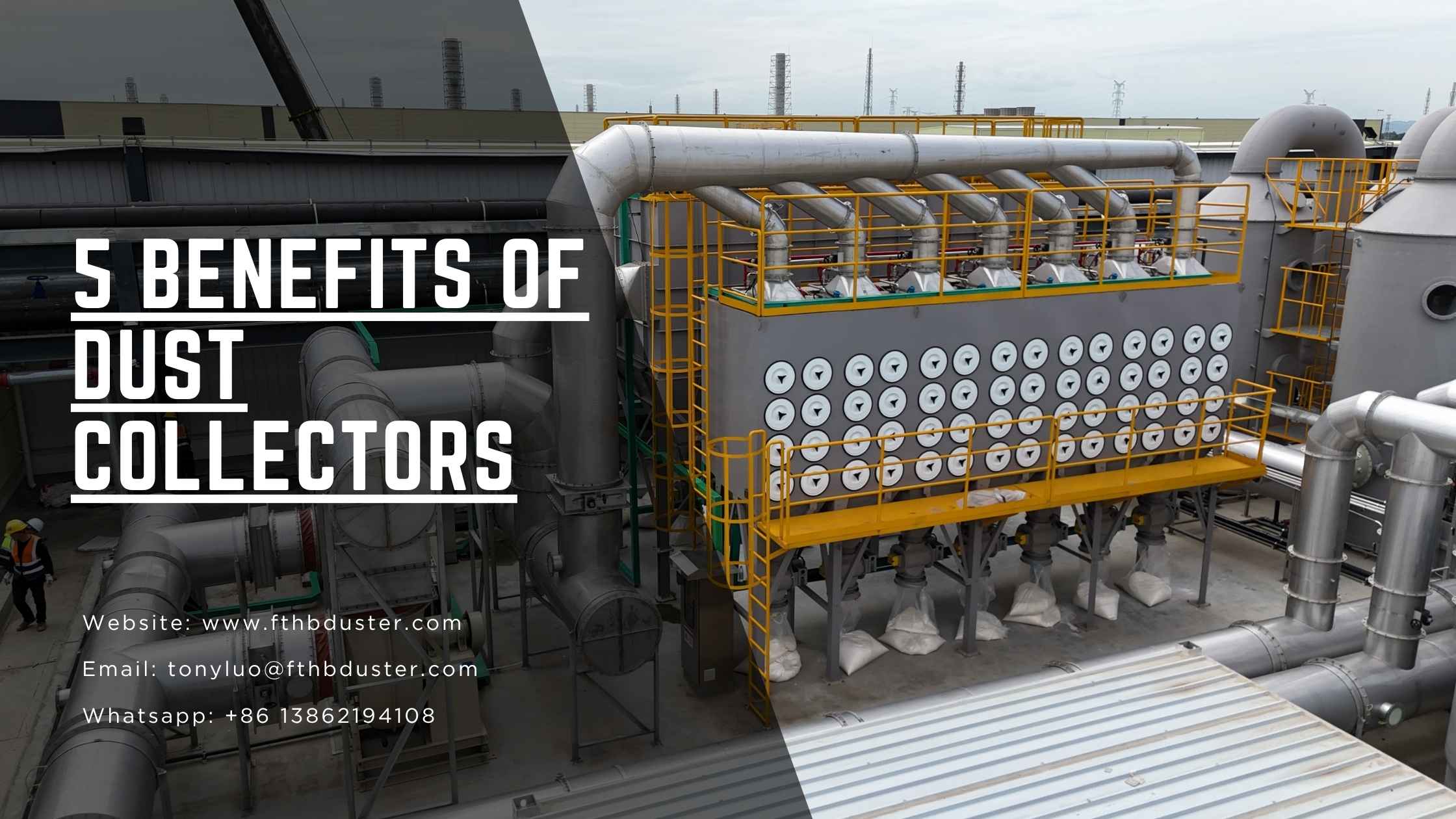

Baghouse & Cartridge Dust Collectors: The Ideal Choice for Abrasive Dust

When we design a solution for your abrasive blast dust collector needs, we primarily turn to two proven technologies: the Baghouse Dust Collector and the Cartridge Dust Collector.

The Baghouse Dust Collector: Heavy-Duty Performance

A Baghouse Dust Collector is an excellent choice for heavy-duty applications. It uses large fabric bags to capture even the smallest dust particles. When the bags are full, a pulse-jet cleaning system automatically shakes or pulses them to release the trapped dust into a hopper below. This type of sand dust collector is robust, reliable, and requires minimal maintenance, making it a great long-term investment for your factory.

When to choose it: Ideal for applications with high dust loads and larger particle sizes, or when you need a system that can handle tough, continuous operation.

The Cartridge Dust Collector: Compact & Highly Efficient

The cartridge dust collector is a compact, high-efficiency solution, perfect for applications like the sand blast cabinet dust collector and sand blasting cabinet dust extractor. It uses pleated filter cartridges that offer a large surface area in a small footprint. This design allows for superior filtration efficiency and is particularly effective at capturing the fine dust created in processes such as sand blast dust collector.

When to choose it: A great option for smaller workspaces or when you need a powerful, space-saving system. We often recommend it for systems like the sand blasting dust extractor or blast cabinet dust collector. the default text, you can click here to add the text content you want to render.

Beyond the Product: Your Partner in Dust Control Solutions

At Fengtu, we understand that a one-size-fits-all approach doesn't work. The right solution for your sandblast room dust collector or blast room dust collector depends on factors like the type of media you're using, your factory layout, and specific airflow requirements. That's why we don't just sell you a box; we provide a complete engineered solution.

Why Global Manufacturers Trust FengTu®

When it comes to abrasive blasting dust collection, FengTu® is more than an equipment supplier—we’re your engineering partner. Here’s why leading manufacturers around the world choose us:

Global Reach: From Asia to North America, we’ve deployed systems in over 20 countries

Total Customization: Each system is built-to-spec, based on your media, layout, airflow needs, and regulations

Technical Expertise: Our engineers understand the behavior of abrasive dust, and design around your pain points

Service and Support: From CFD simulation to onsite commissioning and training, we support you at every step

Ready to upgrade your blasting dust control? Contact FengTu® today for a free consultation and engineered quote.