Four Critical Problems One Comprehensive Solution

Severe Workshop Dust Pollution

Fengtu’s high-efficiency cartridge dust collectors achieve up to 99.98% dust capture, creating a cleaner, healthier working environment.

Struggling to meet emission standards

All systems are fully compliant with local environmental regulations and international standards, ensuring worry-free operations.

Outdated equipment with high energy use and poor filtration

Our smart variable-frequency system delivers high-performance filtration while significantly reducing energy consumption.

Dust contamination affecting product quality and consistency

Advanced dust collection technology ensures a stable, dust-free production environment, lowering defect rates and improving consistency.

Our Dust Collector Product Lines

Baghouse Dust Collector

Ideal for heavy dust loads, providing high-efficiency filtration for a wide range of industrial applications.

Cartridge Dust Collector

Offers a compact design and high filtration efficiency, perfect for fine dust and small to medium-sized spaces.

Cyclone Dust Collector

Excellent for large particles and high dust volumes, serving as an effective pre-separator to extend filter life.

Sintered Plate Dust Collector

Engineered for harsh environments, offering superior durability and long-term performance for sticky or abrasive dust.

Portable Dust Collector

Highly flexible and mobile, designed for on-the-spot dust control and localized filtration needs.

Activated Carbon Adsorption System

Specialized in absorbing VOCs and odors, providing effective treatment for harmful gaseous pollutants.

Spray Tower Scrubber

Utilizes a wet filtration process to effectively remove water-soluble particles and gaseous contaminants from the air.

Customized Dust Collector

Tailored solutions built to match your unique factory layout, specific production process, and compliance requirements.

Download Full Product Specifications

- Thumbnail

- Name

- Update

- Size

- Download

-

- FengTu Dust Collector Catalog.pdf

- 2025-04-28

- 17.65MB

- Download

Custom-Engineered Dust Collectors for Every Application

Fengtu Industrial Dust Collector Components & Options

Filtration System

Filter bags / cartridges (Polyester, Acrylic, Aramid, PTFE membrane)

Pleated or high-surface-area filter elements

One-piece or two-piece support cages / filter frames

Cleaning System

Pulse-jet valves and piping

Mechanical shaking / reverse-air cleaning

Walk-in or accessible cleaning chambers

Housing & Structural Components

Materials: Carbon steel, anti-corrosion coating, Stainless steel 304/316

Shapes: Square, rectangular, circular, high-pressure design

Top/bottom/side air inlets, hoppers, and dust collection bins

Safety & Accessories

Explosion-proof / fire-resistant design

Platforms, ladders, support structures, access walkways

Inspection doors / observation ports

Airflow & Duct Components

Inlet and outlet flanges, duct connections

Air distribution plates / guide vanes

Cyclone pre-separators / coarse dust separators

Automation & Control

PLC intelligent control

Differential pressure monitoring and alarms

Variable frequency fan control, remote monitoring

Special Features & Options

Wear-resistant / corrosion-resistant liners

High-temperature or high-humidity applications

VOC adsorption (activated carbon), wet scrubbers

Mobile / modular / multi-inlet designs

Value-Added Services & Accessories

Custom engineering and design services

Easy-maintenance components, quick-change filters

Installation and commissioning support

Spare parts and consumables supply

Operator and maintenance training

Long-term performance monitoring services

Your Partner in Profitability and Compliance

Compliance with Environmental Regulations

Ensure Regulatory Compliance. Our advanced dust collectors are engineered to meet and exceed strict local and international environmental emission standards, keeping your factory in full compliance.

Increased Profitability

Boost Your Bottom Line. By reducing maintenance downtime, reclaiming valuable raw materials, and improving overall production efficiency, our solutions directly contribute to your company’s profitability.

A Clean and Safe Production Environment

Create a Healthier Workspace. A clean, dust-free environment protects your employees' health, boosts morale, and ensures the quality and precision of your products.

Lower Your Operating Costs

Old dust collectors drain your budget with high energy use and complex maintenance. Our intelligent control systems and variable frequency drives (VFD) offer a smarter way to save, significantly cutting your power bills. The result is a more efficient and reliable system that directly reduces your factory's expenses.

Our Track Record

| Time | Country | Industry | Air Volume | Common Dust Issues | Our Solution |

| 2016.9 | Thailand | Woodworking | 15,000 m³/h | Wood chips, shavings, and fine sawdust, posing flammability and explosion risks. | Cyclone pre-separator + Cartridge Dust Collector with an explosion-proof discharge device. |

| 2017.5 | Vietnam | Textile Mill | 12,000 m³/h | Cotton lint, fibers, and fine cotton dust, which easily clog pipes and equipment. | Customized Baghouse Dust Collector with anti-stick filter materials and a special cleaning method. |

| 2018.8 | Malaysia | Food Processing | 8,000 m³/h | Combustible flour, sugar, and spice dusts, with hygiene and explosion risks. | Stainless Steel Cartridge Dust Collector with an explosion-proof design and food-grade hygienic standards. |

| 2019.2 | Philippines | Chemical Industry | 18,000 m³/h | Toxic, corrosive gases and chemical dusts, posing threats to worker health and the environment. | Spray Tower Scrubber + Activated Carbon Adsorption System. |

| 2020.10 | Saudi Arabia | Power Plant | 30,000 m³/h | Fumes and fly ash from the combustion of coal and petroleum coke, with strict emission requirements. | High-temperature Baghouse Dust Collector with an efficient cooling system. |

| 2021.6 | South Korea | Electronics Manufacturing | 6,000 m³/h | Micron-sized metal dust and harmful gases from precision machining. | Modular Cartridge Dust Collector that is compact and highly integrated. |

| 2022.4 | Australia | Mining | 22,000 m³/h | Dust from mining and transportation of coal and iron ore. | Sintered Plate Dust Collector with high wear resistance and a long lifespan, suitable for harsh environments. |

| 2023.11 | United Arab Emirates | Precast Concrete | 10,000 m³/h | Concrete and sand dust that is dry and abundant. | Portable Dust Collector for high flexibility, suitable for various work points. |

From Design to Delivery: Our Manufacturing Process

At FengTu, every step of your dust collector’s journey happens under one roof—from engineering design and sheet metal cutting to welding, assembly, testing, and packaging. This means faster lead times, better quality control, and flexible customization to your needs.

Not All Dust Collectors Are Tested Like Ours

Airflow & Volume Balance Testing

Each unit undergoes air volume and flow distribution testing to ensure smooth, balanced airflow without turbulence—maximizing filtration efficiency while minimizing energy consumption.

Sealing & Leakage Inspection

We perform smoke tests and particle leak detection to guarantee tight sealing of all joints and access points, achieving ≥99.98% filtration efficiency with leakage kept under 2%.

Pre-Assembly & On-Site Simulation

Smart Control System Calibration

Each PLC-based control system is rigorously configured and tested for accurate differential pressure monitoring, cleaning intervals, and temperature alerts—enhancing automation, safety, and peace of mind.

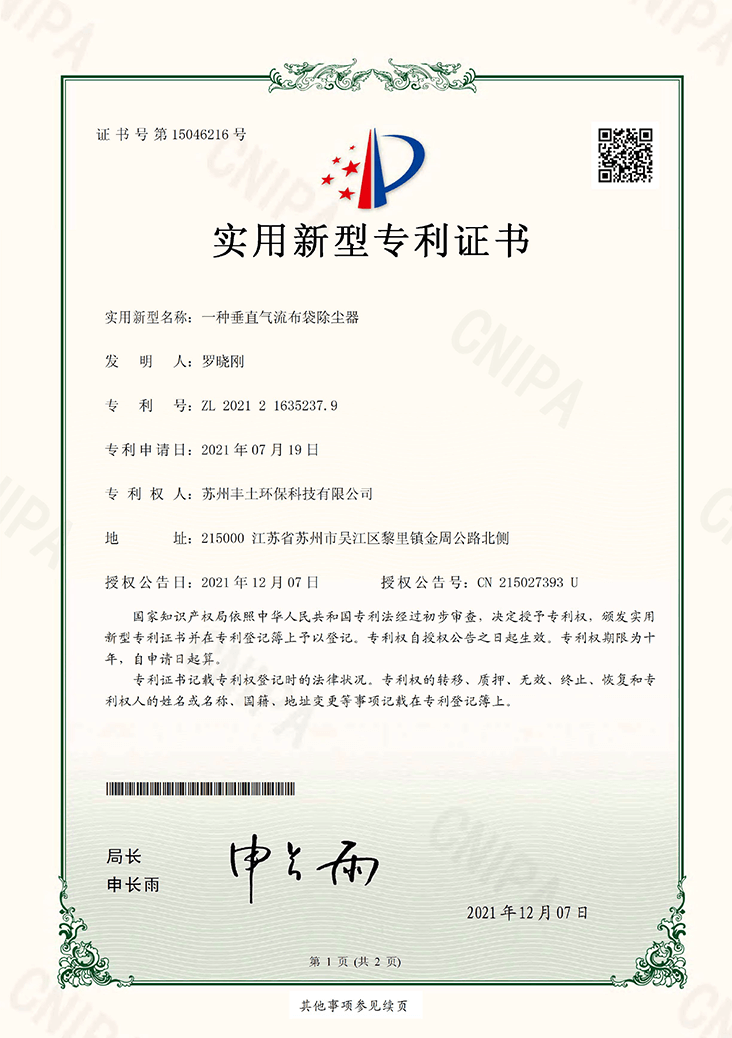

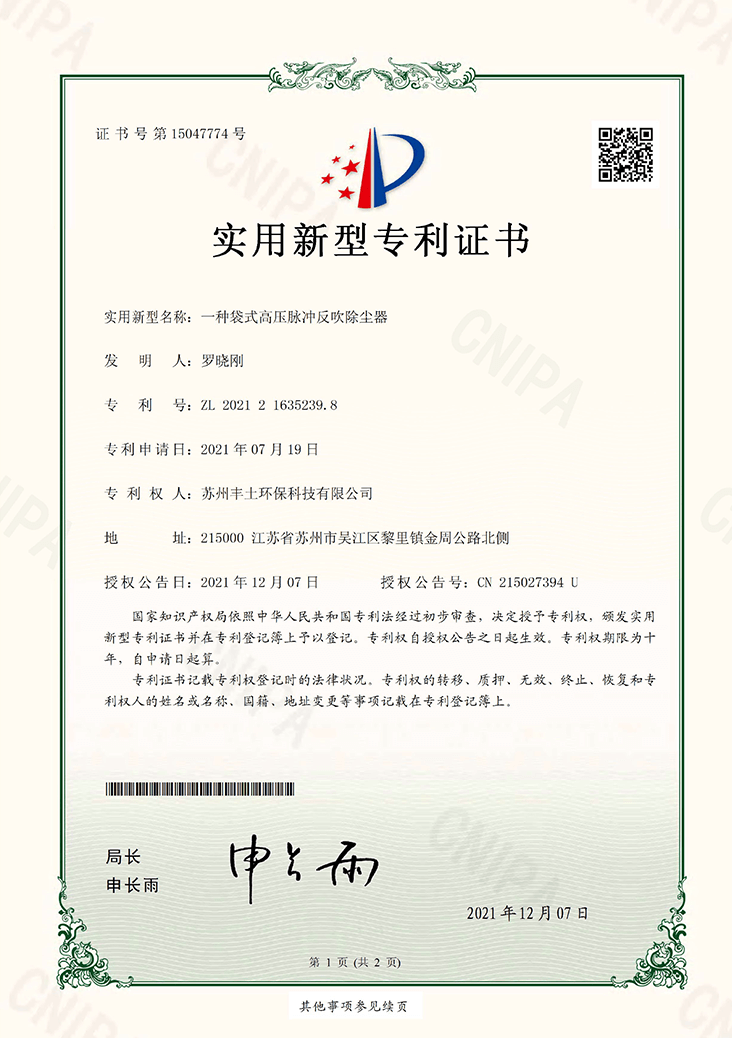

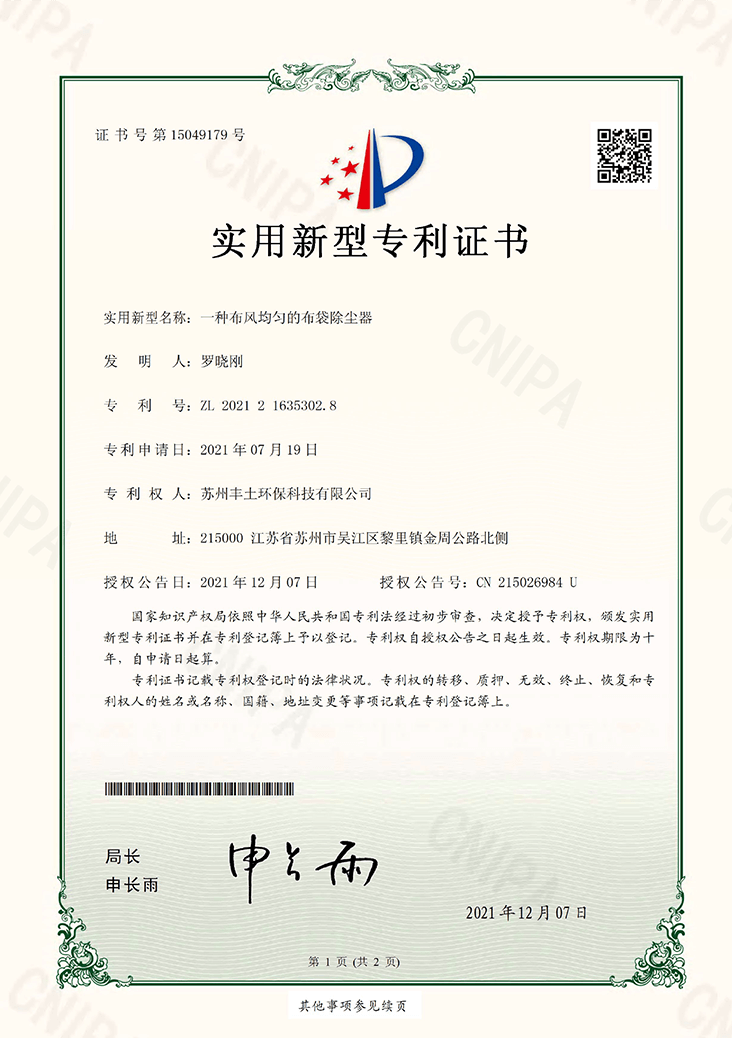

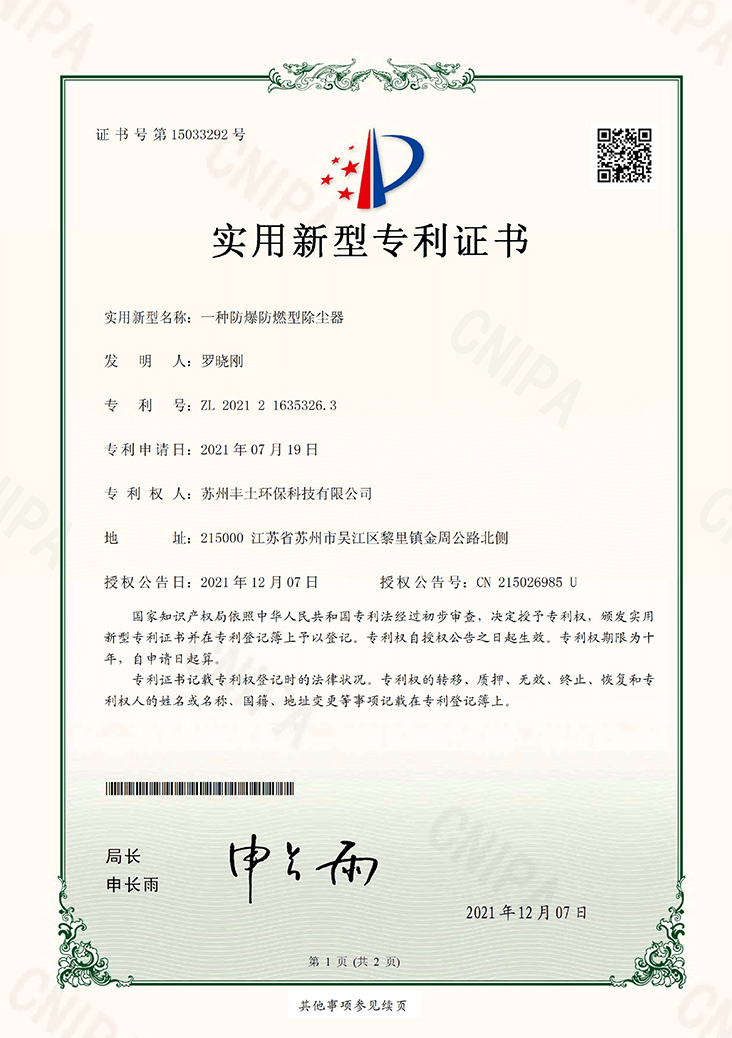

Certificates

How To Get a Quote

How to Get a Quote in 3 Easy Steps

Submit Your Requirements

Fill out the form with details about your industry, dust type, and application needs.

Receive a Customized Solution

Our engineers will review your request and prepare a tailored dust collection proposal.

Get Your Quote & Demo

You’ll receive a detailed quotation along with a free demo or technical consultation.